Within two miles of each other in western Pennsylvania are

the two largest hospitals among those served via the University of

Pittsburgh Medical Center (UPMC) system. UPMC Presbyterian, a 997-bed

academic hospital, is designated as a Level 1 Regional Trauma Center. UPMC

Shadyside is a 517-bed tertiary-care facility. In 2008, Presbyterian and

Shadyside clinical chemistry laboratories processed 4.5 million and 1.09

million billable tests, respectively. With test

volumes increasing yearly by 8% to 10%, implementing technologies to meet

their high-volume 24-hour testing demands was critical. In a concerted

effort to standardize laboratory testing and improve patient care, UPMC

sought total laboratory automation.

Choosing an automated system

The laboratory leadership employed a multidisciplinary

group to evaluate, select, and implement the “best fit” automation system.

The Laboratory Automation Group (the Group) included laboratorians (clinical

chemists, pathologists, and medical technologists), laboratory information

system (LIS) analysts, clinicians, nurses, and representatives from the

offices of UPMC's Facilities Management, as well as its Center for Quality

Improvement and Innovation.

The overall goal was to improve patient care through

accuracy and consistency in laboratory analyses. The strategic goals of the

UPMC Automated Testing Laboratories were to:

- install new chemistry and immunochemistry

analyzers, and an automated platform with sample management

capabilities; - integrate sample analyses and sample management;

- improve and standardize test turnaround times

(TAT), and improve the management of analyses through interactive

management software (middleware); - reduce multiple blood collections and aliquot

preparation; pre-analytical, analytical, and post-analytical errors; and

operation costs; - minimize laboratory staff exposure to biohazards

associated with sample processing; and - increase test-volume growth potential.

The Group's first overall task was to identify companies

with commercially available laboratory-automation systems capable of

satisfying the overall objective. The Laboratory Automation Group was then

separated into five teams. While supporting the Group's main objective —

improving patient care through accuracy and consistency in lab analyses —

each team delineated its specific needs. The Sample Management team sought

automation technologies requiring minimal operator intervention for sample

acquisition, sample integrity assessment, centrifugation, aliquoting,

storage, and sample retrieval.

The Instrument and Methods team wanted automation systems

that offered comprehensive chemistry and immunochemistry test menus with the

potential of test expansion. At the time of the project, the labs' analyzers

were supplied by a variety of companies; identifying one that offered both

general chemistry and immunochemistry analyzers was important. Cost of

operation, as well as system reliability and flexibility, were equally

significant.

The LIS team itemized the cost of potential software

upgrades needed to ensure the highest performance of the automation system.

The system's scalability and its ability to satisfy security and regulatory

compliance were also determined.

The Site Planning and Facilities Preparation team

assessed the facility infrastructure needed to support the new automation

system. This included evaluation of such factors as appropriate space

accommodation for both staff and instruments, wiring for normal and

emergency power, additional lighting, water access and drainage, and

appropriate ventilation.

The Transition to Automation System team evaluated the

companies' technical support, user training courses, and continuing

education sessions. This team identified areas in the laboratories' current

workflow processes that needed to be addressed prior to the implementation

of the new automation systems.

Automation improves workflow

After a thorough review of four commercially available

automated laboratory systems, the Group selected one that demonstrated cost

efficiency, user friendliness, reliability, and robustness. The total

laboratory automation system installed in March 2009 at Presbyterian

(February 2009 at Shadyside) is comprised of sorters, centrifuges,

aliquoters, general chemistry and immunochemistry analyzers, and a

refrigerated storage (stockyard) — all connected to a robotic track. Samples

are automatically managed once loaded into the inlet station by the

operator. The system scans the bar-coded sample, and the patient

demographics and test requests are downloaded.

Periodically, samples are scanned as they are transported

along the robotic track, allowing the operator to be cognizant of samples'

locations at all times. The system loads and unloads centrifuges, de-caps

samples, and detects sample volume. Samples requiring additional offline

testing are aliquoted from primary tubes to daughter tubes by the system.

Samples analyzed online are routed to the online chemistry and

immunochemistry analyzers.

Following analysis, samples are re-capped and transported

to the stockyard (stores up to 3,200 samples). In the event that a physician

requests additional testing from an earlier sample, the automated system

will retrieve the stockyard sample and transport it to the appropriate

analyzer. Samples analyzed offline (in-house or send-out testing) or those

requiring special attention are diverted to the outlet station for operator

intervention.

The automation system manages samples from beginning to

end. The middleware autoverifies results that pass pre-established criteria

and files results to patient records electronically; alerts the operator of

abnormal results that require further review; notifies the operator of the

sample's pre-analytical status; and prompts the operator of samples that

require offline dilution.

“The middleware technology enabled us to implement

autoverification for all chemistry and immunochemistry testing. With the

elimination of manually resulting normal results, the lab staff have more

time to manage critical results,” says Raymond Bezila, MLT, administrative

director for Automated Testing.

In addition to installing total laboratory automation,

the Group also took advantage of re-educating the hospital staff on sample

management. Prior to the automation install, the clinical chemistry labs

relabeled between 40% to 60% of samples received. Relabeling reduced lab

performance because it added a minute to TAT for results. Relabeling has the

potential to introduce identification errors and is not cost effective.

Moreover, the laboratory received a high volume of samples with accompanying

paper requisitions that required manual order entry. Paper requisitions

added three minutes per test order and increased TAT for results.

Another area of concern was tube sizes and types. Before

automation, the lab accepted samples in a variety of tube sizes and types.

It was necessary, however, to standardize the tube sizes since the new

system requires 13×100 vacutainer tubes. The UPMC Automated Line

Implementation Improvement Project was instrumental in developing a learning

module entitled “Correct Collecting, Labeling, and Sending samples to the

Lab: The Right Way Every Time.” The laboratory has seen significant

improvement in sample labeling. The installation of label printers on

hospital units has significantly reduced (by 21%) the volume of paper

requisitions received by the lab. To date, correct tube sizes have been

stocked on every unit, and tube sizes are now standardized between the two

hospitals; 89% of samples received can be placed directly onto the

laboratories' automated systems without operator intervention.

Laboratory optimization

Nine months have passed since the conclusion of the total

laboratory automation project, and performance has been enhanced

significantly. The automation system directly affects the laboratory staff,

the hospital community, and, most importantly, the patients.

“The automated line project represents state-of-the-art

in high-volume laboratory testing,” says Alan Wells, MD, DMSc, and vice

chairman of Pathology. “Laboratorians now have the technology that improves

workflow of routine testing and creates the capacity to focus closely on the

most difficult cases.”

The first six months of operation challenged the

operators as they increased their familiarity with the technology, while the

hospital community became compliant with revised sample-processing

procedures. Since both Presbyterian and Shadyside have identical automation

systems, each campus can perform its own testing; and the need for sharing

samples between the laboratories is reduced. Testing is now standardized

between the two because it is not unusual for patients to receive treatment

at both hospitals.

A meaningful reduction in the recorded volume of samples

that med techs manually handle translates to reduced exposure to biohazards

and reduced risk of injury. Med techs have more time to devote to

troubleshooting critical cases, performing quality-improvement research

studies (in collaboration with residents and researchers), and researching

and developing new assays. Currently, the laboratory staff is being

cross-trained, which not only presents development opportunities for

individuals but also creates depth and flexibility for laboratory

operations.

The hospital community has benefitted from the faster

STAT and routine turnaround times, which are surprisingly comparable and

suggest that in the future, distinguishing STAT from routine testing will be

unnecessary, because all samples will be analyzed STAT. The TATs for add-on

testing have improved and are directly related to the automation system's

ability to retrieve the sample with minimal human intervention. Med techs no

longer have to physically locate and retrieve the specific sample, which

once could take a half hour.

Prior to implementing the automation system, serum

indices were graded by visual inspection. The lab has begun the process of

standardizing the assessment of serum indices. Hemolysis, lipemia, and

icteria are detected via a spectrophotometry method, and semiquantitative

unitless values are provided for each sample on the chemistry analyzer.

Standardization of the pre-analytical, analytical, and post-analytical

phases has an enormous impact on ensuring the reliability of test results.

Patients have benefited with the consolidation of testing because the volume

of blood necessary to perform testing has decreased, reducing the need for

multiple blood draws, thus saving the patient time and discomfort.

The success of total laboratory automation at

Presbyterian and Shadyside is a direct result of teamwork among the vendor,

laboratory leadership and staff, and the hospital community. Implementation

of total laboratory automation requires change for the laboratory staff as

well as for the hospital community (nurses, phlebotomist, and clinicians).

Automation is not a substitute for laboratory personnel but a complementary

technology that aids in optimizing laboratory performance.

As performance through automation continues to be

optimized, the clinical chemistry laboratories at Presbyterian and

Shadyside now are truly living up to their names as UPMC Automated

Testing Laboratories.

Octavia M. Peck-Palmer, PhD, is assistant professor

in the Department of Pathology at the University of Pittsburgh, and

medical director at the UPMC Presbyterian and Shadyside Automated

Testing Laboratories in Pittsburgh. UPMC includes 15 general hospitals

in western Pennsylvania, related clinics and healthcare facilities, and

partnerships in five international hospitals.

Applying LEAN management to automation

By Scott Henwick, David Chow, and Sabrina Smith

Faced with shrinking budgets, growing volumes, and

personnel shortages, clinical laboratories are increasingly moving to

automation to maximize output and efficiency. But some are finding that

the anticipated rewards of automation are not necessarily automatic. In

fact, such moves may actually highlight a lab's hidden operational

inefficiencies, as getting samples to the automated system becomes the

critical link and the rate-limiting step. This, however, can present an

opportunity to implement LEAN practices in order to reap the full

benefits of automation.

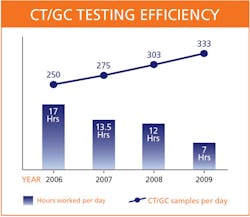

This was the case with BC Biomedical Laboratories in

2006 when we increased the level of automation to address our rapidly

growing Chlamydia trachomatis (CT) and Neisseria gonorrhoeae (GC) testing volumes. BC Biomedical is the

largest physician-owned lab in British Columbia, Canada, serving 1.8

million patients and running 25,000 tests per day. At the time, our

CT/GC testing volume was at 250 samples per day and rising by about 10%

per year.

We acquired a system which replaced manual pipetting

involved in sample transfers, amplification, and analysis steps with

robotics, with the objective of saving time as well as reducing manual,

repetitive tasks. We incorporated the new system into the current workflow

and quickly realized that our processes, which were previously adapted to

manual CT/GC processing, were not taking full advantage of the automation

the new system could deliver. We questioned if we could achieve higher

productivity by adjusting how we handle pre- and post-analytical steps, as

well as those that interact with the system. In order to make process

changes that would maximize the productivity and efficiency of the new

system, we turned to LEAN.

Specifically, we invited a LEAN/Six Sigma consultant to

perform a process review. He worked with our entire team of two clinical

supervisors, 30 medical technologists, and 15 lab assistants for three days

examining and applying LEAN principles to each step of our CT/GC sample

processing. What followed was a journey toward enhanced productivity and

cost efficiency, which inspired our staff to apply this continuous

improvement tool across all aspects of our work.

We worked with the consultant to make changes that

brought dramatic productivity improvements in just the first few days. This

gained the immediate support of our entire team — many of whom had been

hesitant to change — for the LEAN process. Over time, we implemented more

than 200 process improvements throughout the department, many of which were

small, incremental changes but all of which contributed to dramatic

productivity gains.

A new way of looking at workflow

Working with the consultant, the first thing we did was

to adopt the “single-piece flow” approach, a core tenet of LEAN, to sample

processing. Single-piece flow embraces the importance of considering each

sample individually, rather than as part of a batch in order to avoid

build-up of samples at any given stage, thus improving efficiency.

Specifically, decisions are made about each sample in real time as it moves

through the system, and problem samples are set aside for processing later

so they do not delay other specimens.

The single-piece flow concept also helped us think

differently about how we use the instrument. For example, we started

preparing the specimens when we had just one of two trays full (46 samples),

rather than waiting for a full batch of specimens on both trays (92

samples). This enabled us to reduce instrument lag time every morning and to

complete the runs earlier each afternoon. We also began processing samples

at the end of the day, so they would be ready the next morning. This

decreased instrument lag time in the morning from 90 to 30 minutes — which

freed up our techs for other tasks while the machine is running.

One area where single-piece flow helped eliminate waste

was in the central-processing area. This is where samples first arrive in a

large bin from doctors' offices and are labeled and entered into the LIS

system. Prior to LEAN implementation, we would enter all samples from that

box, label them all, and then return them to the bin unsorted. This approach

was inefficient since it created a lag in the system and was prone to

labeling errors. By mapping and optimizing the accessioning process, we

saved about 30 minutes in the first iteration of the new process. As we

further optimized the process by running pilot projects and refining the

physical workspace, the incremental time savings added up. Additionally,

this change to single-piece flow helped cut errors in central processing by

22%. By working with one specimen from beginning to completion, single-piece

flow eliminated the potential for mislabeling specimens.

Standardizing the work

Standardization of work processes is another fundamental

LEAN principle. Previously, each staff member had developed his own way of

performing various manual tasks. These included creative “work-arounds” for

typical process problems that might arise. When we installed a more

automated instrument and tried to apply to it our ad hoc processes, our work

system did not run smoothly, especially for processes that required a

handoff to another person. In contrast, by standardizing how we performed

each process, we were able to identify and institute best practices.

For example, previously, each technologist had his own

technique for loading samples into the instrument racks. The technologist

would typically label the sample before placing it in the rack and would

later go back to pick up each sample from its slot in order to scan the bar

code. To streamline the process, we established that all bar codes would be

scanned before being applied to the samples and that all samples would be

stacked from right to left, beginning in the back. These changes enabled us

to save 20 to 40 minutes per day. Additionally, by loading samples from

right to left, we were able to avoid having to move the wand cord out of the

way each time we loaded a sample. This allowed us to save a couple of

seconds per specimen, which by the end of the day could add up to several

minutes.

We also standardized work areas. For example, we used to

organize work lists into binders. For greater efficiency, we organized

paperwork into folders, each labeled by day of the week. We also color-coded

the racks to easily identify them. Additionally, we taped off and labeled

each work area. These changes enabled us to save several minutes each day.

Further, the physical separation of the specimen handling area from other

tasks such as administrative tasks minimized the risk of contamination.

Further, we reconfigured work spaces so that we all worked from left to

right, in a linear fashion. This increased efficiency and further minimized

risk of contamination.

Measurable benefits

In just two years, BC Biomedical's CT/GC volume increased

22% to more than 300 samples per day, while we maintained our current head

count of two technologists plus one-quarter of a lab assistant's time

dedicated to CT/GC testing. Our current staffing level for this bench can

handle an additional 25% capacity due to the continual process improvements

we have made in this area. Further, we are now able to complete the day's

CT/GC run by 2:30 p.m. vs. 5:30 p.m. previously. This means that doctors are

more likely to get results and, thus, may be able to treat patients a day

sooner.

Our adoption of LEAN has also produced less quantifiable

benefits, namely, reduced stress level of our staff, boosted staff morale,

and superior staff retention. All levels of our staff feel empowered because

each one has had a voice in our LEAN implementation. While our consultant

gave us the initial ideas for how to implement LEAN systems, our staff came

up with most of the process changes we implemented — and continue to

challenge ourselves to further improve our processes.

The move to LEAN has also changed how we communicate with

one another. We now have daily five-minute team meetings, usually first

thing in the morning, during which we identify and resolve work-process

issues we are experiencing. This enables us to fix problems quickly and

makes weekly staff meetings much more efficient. We also put in place a

formal workflow review process, which we conduct at least twice a year as a

group. Our LEAN efforts for CT/GC testing were so successful we were then

able to secure management approval to implement LEAN management throughout

the microbiology lab. We subsequently deployed it to the parasitology,

bacterial I.D., resistance testing, and blood-culture areas, all with

similar success.

Looking ahead

We plan to continue applying LEAN principles to work

processes, particularly as we further increase automation throughout the

lab. We have recently installed the next-level, fully automated system that

incorporates DNA extraction for the ever-growing CT/GC volumes. This time,

the move to increased automation is paying off immediately: In workflow

analysis, we are achieving completion of testing duties by 11:30 a.m. and

are utilizing about half of the FTE component compared to the current

methodology.

LEAN has given us tools to better assess the actual

workload impact of bringing any new technology into the laboratory.

Additionally, with LEAN we are now more confident that before we go “live”

with production, we have mapped out the process to a more efficient starting

state. And by standardizing work processes, we have created a common

baseline upon which to run pilot projects to continuously improve the

process.

Our success with LEAN in the microbiology department has

also prompted its adoption across the entire organization. The lessons

learned in microbiology about single-piece flow, eliminating waste, and

standardization of work processes are now being applied successfully to all

areas of the organization.

Scott Henwick, MD, F(RCPC), clinical director of microbiology,

David Chow, manager of microbiology and parasitology; and

Sabrina Smith, supervisor of microbiology — all

employed at BC Biomedical Laboratories Ltd. in Surrey, British Columbia,

Canada — used a BD Diagnostics' LEAN/Six Sigma consultant, and first

installed a BD Viper System, which was followed by the installation of the

BD Viper System with XTR technology.